PCB DFM solutions by Valor

Valor DFM Solutions

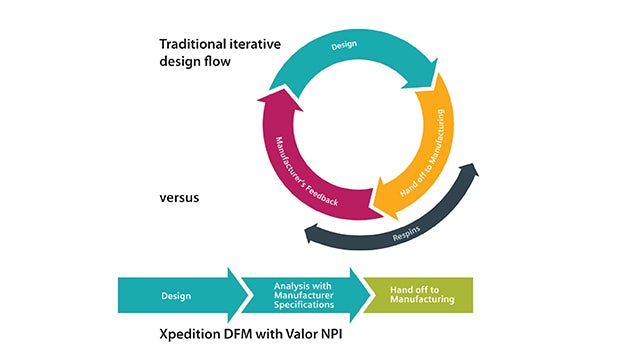

Valor DFM Solutions, Siemens’ design-to-manufacturing platform centered on Valor NPI, brings manufacturing intelligence directly into the PCB layout environment.

Quality through automation

Connect Group: Powered by Valor NPI

Company:Connect Group

Location:Kampenhout, Belgium

Product:Electronic Manufacturing and Technology Services

Size:Medium

Siemens Software:Valor NPI

Tomorrow's Vision:Time is money. That is why the Connect Group brings DFM in at a very early stage in the product lifecycle. Anticipating problems in production and incorporating testing into design help create a win-win system for the Connect Group and their customers.

Valor DFM Products

.jpg?auto=format,compress&w=640&h=360&q=60&fit=crop)