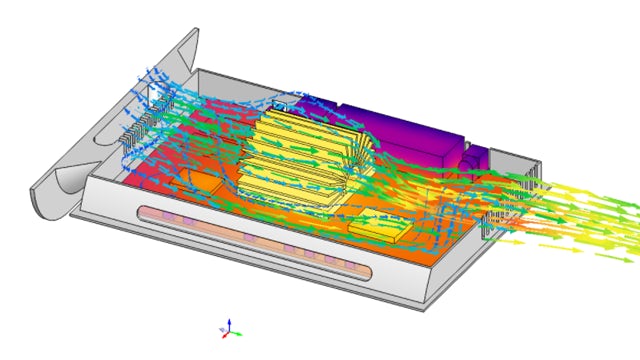

Introducing: next generation electronic systems design

The challenges faced by electronics engineers and organizations today are significantly different from what they were just a few years ago. Recognizing this changing global landscape, Siemens has undertaken the development of a next-generation electronic systems design solution that not only addresses current needs but also anticipates future challenges. Watch this video to learn more!

Solve electronic systems design challenges

Electronic systems design products

Ready to transform your electronic systems design flow? Our product portfolio delivers digitally integrated electronics systems ideation and design solutions so that you can create market-winning products.

EXPLORE ADDITIONAL RESOURCES

-640x360.jpg?auto=format,compress&w=640&h=360&q=60&fit=crop)