Three-phased approach to supply chain resilience

Once you understand the state of the electronics supply chain, it’s important to shift supply chain resilience to the point of design. This can be done through three key phases:

Knowledge

Empower your engineers and teams at point of design with real-time component sourcing knowledge.

Intelligence

Adapt quickly to supply chain electronics disruptions. Employ comprehensive intelligence to manage component data, adapt to supply chain volatility, and improve cost versus risk tradeoffs.

Optimization

Enable engineering teams to proactively design with supply chain constraints at the start. Use integrated, closed-loop component management with built-in traceability.

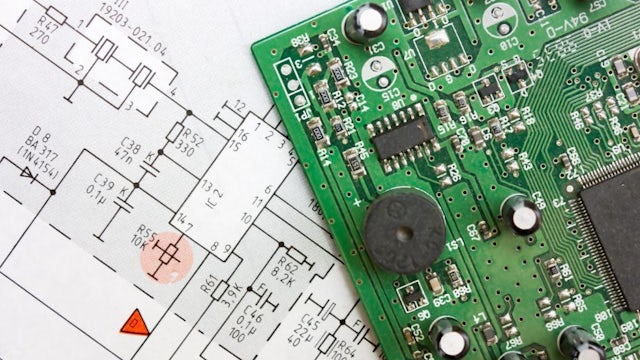

Enabling design for supply chain resilience

In this 15-minute webinar you will gain insight into the current state of the PCB supply chain problem and learn how Siemens is advocating for and enabling the shifting left of supply chain intelligence to the point of design to empower engineers when they need it most. After you watch this webinar check out the video below to see our solution in action through three use cases.

PCB supply chain resilience with Xpedition EDM

The Xpedition EDM supply chain solution includes comprehensive part intelligence from Siemens Supplyframe on over 650 million manufacturer part numbers and includes a data model and automated integration with your engineering workflow. Watch this video to see three use cases: part intelligence, extended search, and part compare.

PCB supply chain resources

Learn more about the current state of the PCB supply chain problem and explore our proposed solutions by checking out our blogs, podcasts, and white papers.