Digital prototype-driven verification

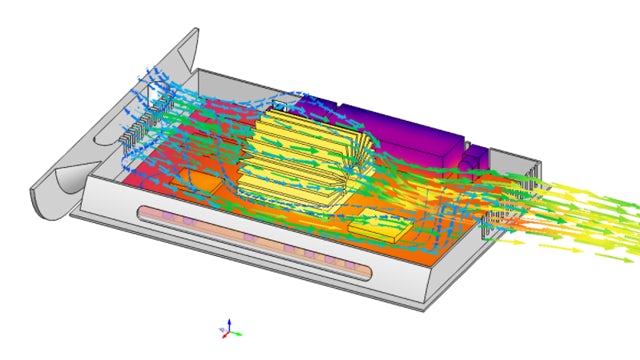

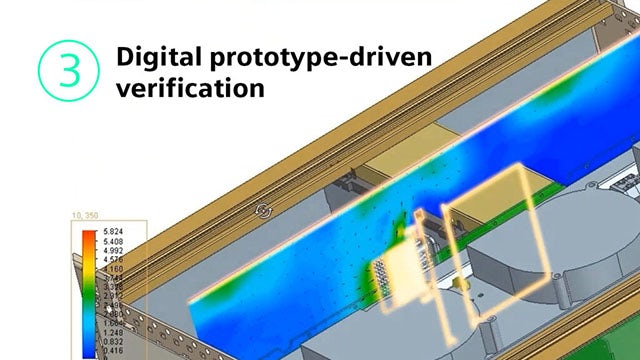

Shift-left design methodology integrates design verification tools throughout the PCB design process to let designers find and fix errors where they happen, instead of waiting until later.

PCB DESIGN BEST PRACTICES VIDEO

Digital-prototype driven verification

In this video Stephen Chavez breaks down the importance of PCB design best practices that can enable digital-prototype driven verification. These best practices include a shift left approach to schematic analysis, thermal analysis, signal integrity, power integrity, and manufacturability.

Digital prototype-driven verification resources

Learn more about PCB design best practices that can enable digital-prototype driven verification. These best practices include a shift left approach to schematic analysis, thermal analysis, SI/PI, AMS and manufacturability.