Xpedition Substrate Integrator (Legacy)

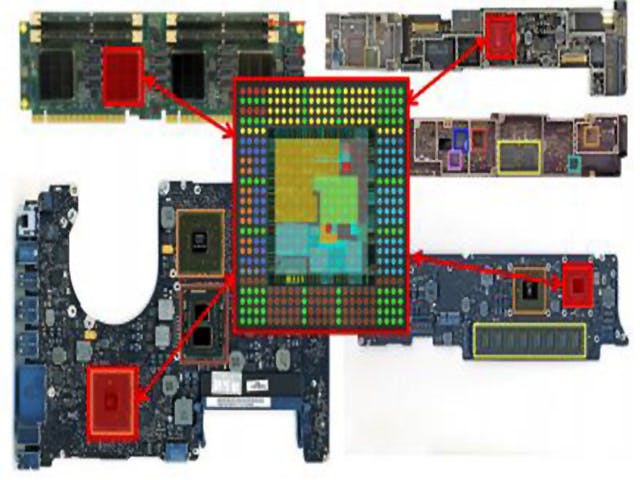

Heterogeneous and homogeneous 2.5/3D IC Package Connectivity Planning, assembly prototyping, & system technology co-optimization.

2.5/3D IC Package Planning & Prototyping

Early prototyping and exploration allows engineers to evaluate different ASIC/chiplet, interposer, package, and PCB integration scenarios in order to meet overall PPA, device size, routability, and cost goals prior to detailed physical implementation.

Key features of Substrate Integrator

Full or Partial Schematics Import

IC package assembly logical connectivity can be constructed by using full or partial graphical schematics, useful for high device count designs such as SiP modules and/or the re-use/retargeting of previous designs.

System-level Package Connectivity Management

System connectivity management, visualization, and system-level logical verification of multi-die, multi-component, and multi-substrate IC package designs.

Aggregation of Die, Chiplets & Substrates

Xpedition Substrate Integrator integrates die, chiplets, and interposers from different process nodes and suppliers. Multiple formats are supported including LEF/DEF, GDS, AIF, and CSV/TXT. Hierarchical virtual die models support bidirectional ECO changes of objects under design/optimization.

Silicon-package-PCB Cross Substrate Co-optimization

Cross-substrate planning and co-optimization greatly improve predictability during implementation by finding and fixing issues before they become late-stage surprises. A system perspective with cross-substrate visibility improves communication and coordination through immediate feedback to decisions typically made on an individual substrate basis.

Early Fast Signal Integrity Analysis

Provides an early exploration of SI performance during design planning and co-optimization allowing designers to explore multiple SI scenarios very early in the process while the cost of change is low. Prevents potential issues from reaching implementation causing delays and rework.

Comprehensive 3D Package Verification with Calibre

This verification solution provides extensive and comprehensive capabilities across every level of the package assembly through direct digital integration with Calibre 3DSTACK. By using the actual planned manufacturing data, as opposed to the design tools native database, you ensure that post-processing errors are not introduced.