Overview

Vibration and stress analysis

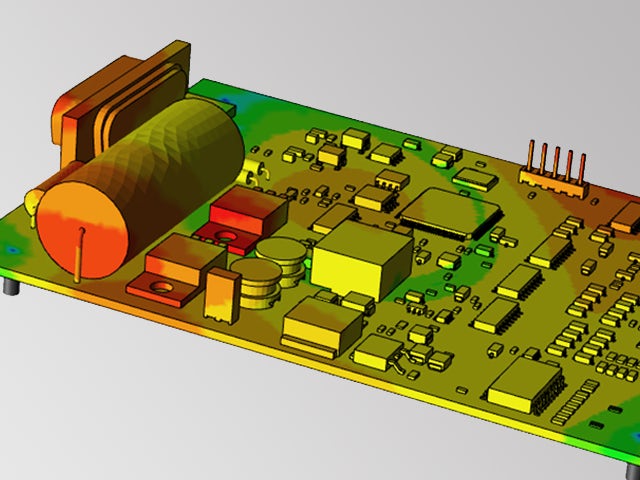

Understanding the physical constraints and fatigue issues for a particular design prior to manufacturing is essential for reducing board failures and decreasing time to market for electronic products.

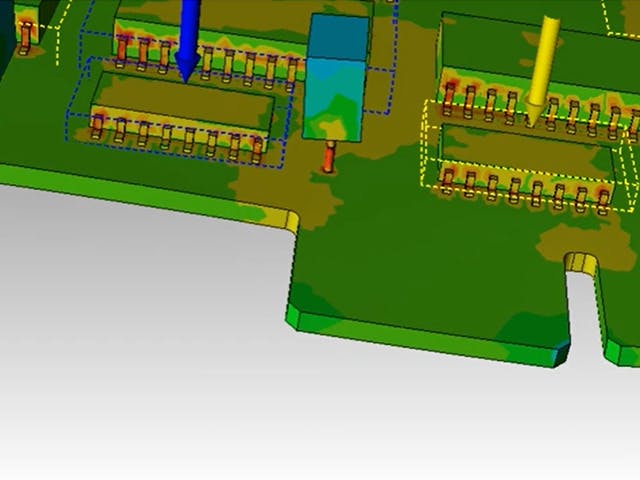

Optimize designs with acceleration & vibration analysis

Xpedition Design for Reliability (DfR) enables early detection of PCB design vulnerabilities due to physical use, reducing costs and shortening cycle time. Xpedition DfR provides two options for quick PCB design simulation: vibration analysis and constant acceleration.

Improve reliability

Adding simulation to the PCB domain frees reliability specialists to focus on critical issues that might otherwise be hidden.

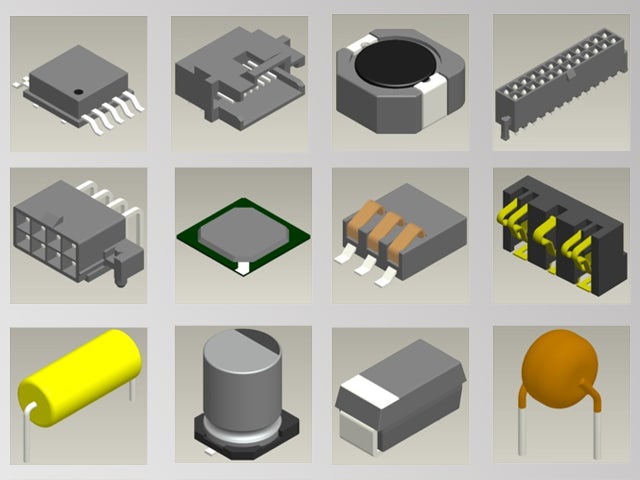

Realistic parts for fast analysis

3D parametric tools and a starter library of more than 4.5 million parts enable accurate simulations and modeling.

Rapid visualization

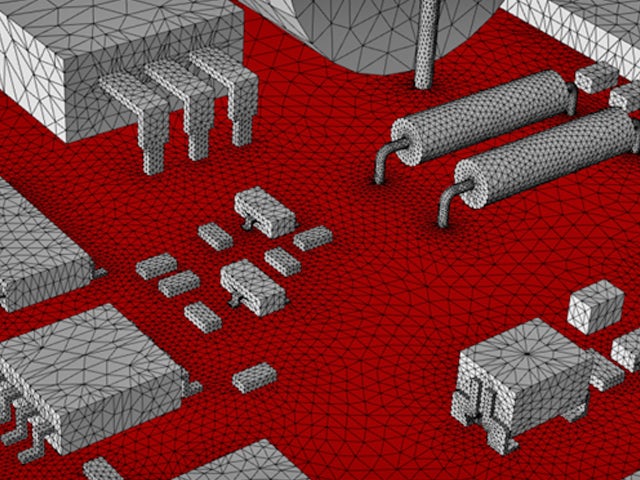

Quickly generate meshed models for full-board simulation during the design process to determine PCB reliability and reduce field failure rates. Simulate vibration effects and detect stresses and failures.