Overview

Calibre Stress Correction

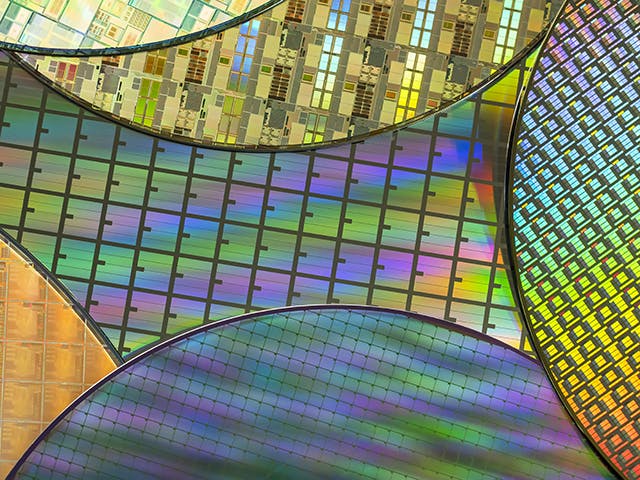

Calibre Stress Correction uses both machinelearning and traditional physical compact models to efficiently predict the shift values on each of the trenches and correct for the trench distortion to ensure manufacturability for 3D memory devices.

Get in touch with our technical team 1-800-547-3000

Key Features

Calibre Stress Correction analyzes and corrects distortion of the deep trenches cut through 3D stacks for advanced memory devices.

Full-chip trench shift prediction for stress correction

Calibre Stress Correction conducts full-chip trench shift prediction and executes the required shape alignment. Both the machine learning engine and the stress correction modeling engine can handle billions of trench shifts for full-chip usage.

-640x360.jpg?auto=format,compress&w=640&q=60)

Machine learning intelligence for complex resolution

Calibre Stress Correction is equipped with a neural network machine learning (ML) model that learns historical trench shift data from previous tape-out regardless of the complicated cause of the shift. ML model learning provides a straightforward way to predict the shift values for stress correction on a new layout with similar design rules and the same process.

-640x360.jpg?auto=format,compress&w=640&q=60)

Model-based prediction without needing historical data

Calibre Stress Correction performs shift prediction by using a compact physical model when the previous shifting information is unavailable. The shift values can be predicted based on the physical parameters in the model and the surrounding layout information without any requirement from the previous shift measurements.

-640x360.jpg?auto=format,compress&w=640&q=60)

Ready to learn more about Calibre?

We're standing by to answer your questions! Get in touch with our team today

Call: 1-800-547-3000

Calibre consulting services

We help you adopt, deploy, customize and optimize your complex design environments. Direct access to engineering and product development lets us tap into deep domain and subject matter expertise.

Support center

The Siemens Support Center provides you with everything in one easy-to-use location -

knowledgebase, product updates, documentation, support cases, license/order information and more.

Design with Calibre blog

The Calibre tool suite delivers accurate, efficient, comprehensive IC verification and optimization across all process nodes and design styles while minimizing resource usage and tapeout schedules.