Missed us at SemiCon Europa 2023? Watch our presentation now!

Enabling smart manufacturing in semiconductor fabs using predictive design and process insights

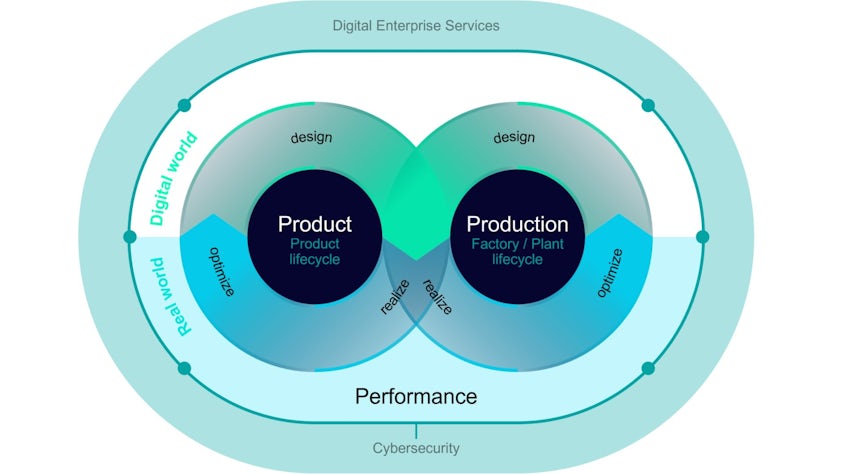

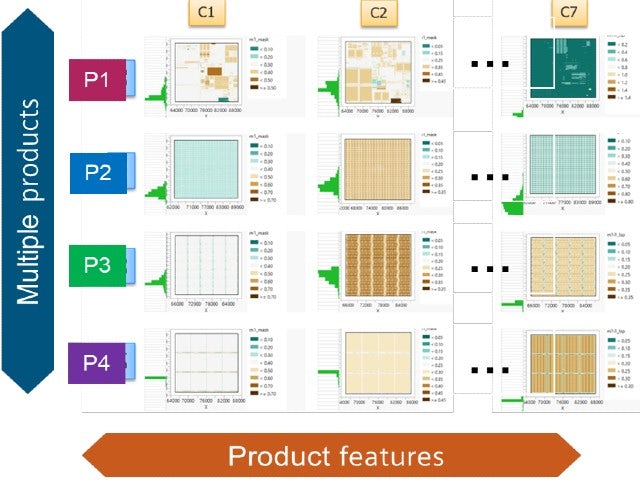

As the semiconductor market continues rapid growth, every part of the design and manufacturing of semiconductor products needs to adopt smarter processes to meet the demand. Designers need to accelerate development, manufacturers needs to ramp yield quickly and maximize the efficiency of the fab, and all parts of the supply chain need to be in sync. For the semiconductor fab, this means implementing a digital twin to reduce iterations between design and production, virtually prototype and develop new processes, and quickly characterize and calibrate every piece of equipment in the fab.

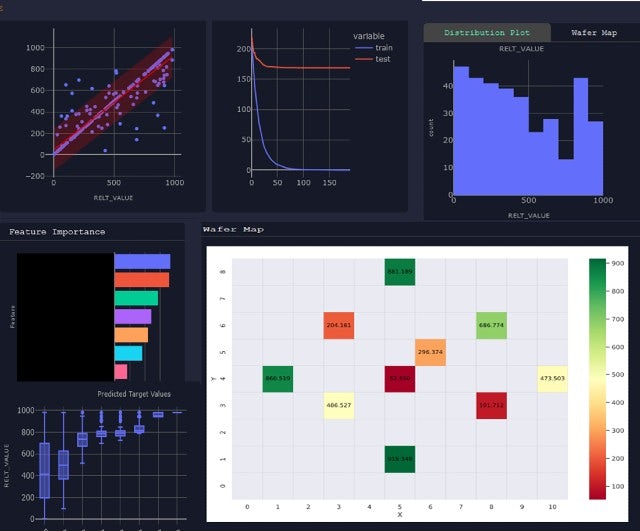

Siemens, a leader in digital twin technology, offers the Calibre Fab Insights platform to help semiconductor manufacturers meet their business and sustainability goals today and into the future.

Using a digital twin with Calibre Fab Insights provides unique business value: new products start production sooner, yield ramp is faster and yield entitlement is higher.