Overview

Calibre nmCLMPC

Mask process correction (MPC) ensures the mask pattern fidelity of advanced node mask manufacturing. Calibre nmCLMPC provides the needed capability for curvilinear mask process correction to meet the expectations for correction accuracy as well as for processing time.

Get in touch with our technical team: 1-800-547-3000

Mask process correction (MPC) for curvilinear designs

Calibre nmCLMPC performs Mask Process Correction (MPC) for input layouts with curvilinear polygons, such as those produced by Inverse Lithography Technology (ILT) OPC, as well as silicon photonic structures.

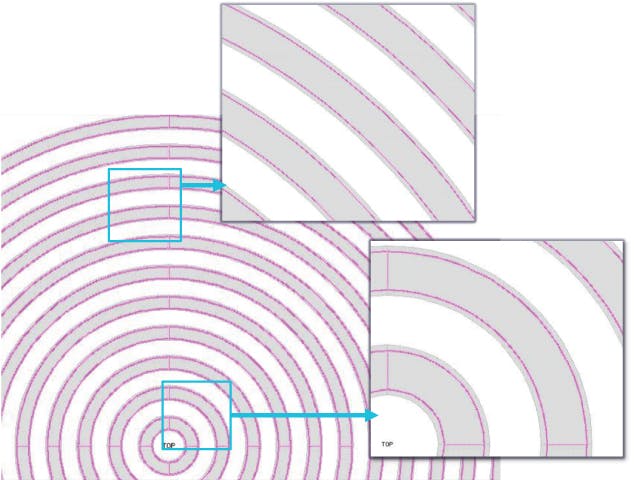

Innovative curvature-based fragmentation

The curvature-based fragmentation in Calibre nmCLMPC engine determines edge fragment length based on local curvature and provides output feasible for curvilinear MPC correction. This feature attempts to co-optimize file size, accuracy and execution time for curvilinear mask process correction.

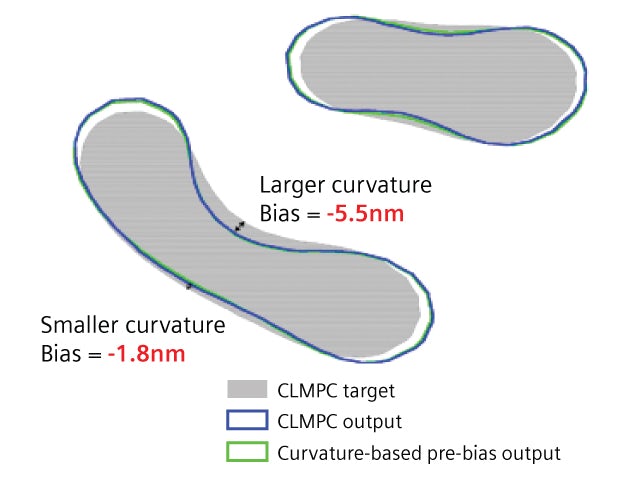

Option to achieve fast convergence

Calibre nmCLMPC can be used with curvature-based pre-biasing to enable fast convergence for curvilinear MPC. The curvature-based pre-bias method reduces the number of iterations required without degrading the correction accuracy and saves runtime.

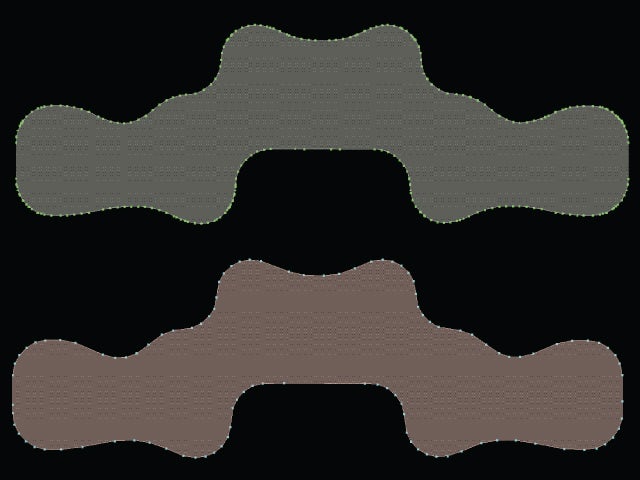

Simultaneous correction capability

Calibre nmCLMPC can correct curvilinear and rectangular shapes in one run applying the same rules as in a standard recipe to the rectangular shapes.

Ready to learn more about Calibre?

We're standing by to answer your questions! Get in touch with our team today

Call: 1-800-547-3000

Calibre consulting services

We help you adopt, deploy, customize and optimize your complex design environments. Direct access to engineering and product development lets us tap into deep domain and subject matter expertise.

Support center

The Siemens Support Center provides you with everything in one easy-to-use location -

knowledgebase, product updates, documentation, support cases, license/order information and more.

Design with Calibre blog

The Calibre tool suite delivers accurate, efficient, comprehensive IC verification and optimization across all process nodes and design styles while minimizing resource usage and tapeout schedules.