Overview

Calibre YieldAnalyzer

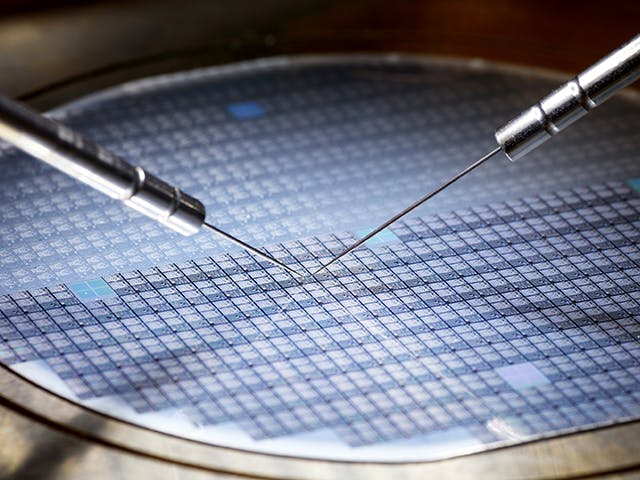

The Calibre YieldAnalyzer tool examines a layout and scores the design for both critical area analysis and DFM scoring. The intuitive interface helps designers analyze the results so they know what, where and how they can most improve their designs for manufacturability.

Get in touch with our technical team: 1-800-547-3000

Comprehensive Solution for Design Optimization

The Calibre YieldAnalyzer tool supports many of the leading foundries. Calibre YieldAnalyzer technology supports CAA, DFM scoring, and via redundancy checking. It helps customers analyze designs so they can optimize layouts for manufacturing.

Enables DFM Scoring

DFM scoring quantifies design sensitivity to a systemic issue as represented by a rule deck. To implement DFM scoring, a rule deck is configured with a list of recommended rules and estimates for weighting factors for each rule, based on foundry-recommended rule priorities.

CAA & Via Redundancy Score Designs for Random Defects

The Calibre YieldAnalyzer tool performs critical area analysis on all base and interconnect layers to identify areas of a layout with excess vulnerability to random particle defects, such as shorts and opens. A CAA deck is configured with the layer information foundry defect density distributions for each process and defect type (open/short).

Ready to learn more about Calibre?

We're standing by to answer your questions! Get in touch with our team today

Call: 1-800-547-3000

Calibre consulting services

We help you adopt, deploy, customize and optimize your complex design environments. Direct access to engineering and product development lets us tap into deep domain and subject matter expertise.

Support center

The Siemens Support Center provides you with everything in one easy-to-use location -

knowledgebase, product updates, documentation, support cases, license/order information and more.

Design with Calibre blog

The Calibre tool suite delivers accurate, efficient, comprehensive IC verification and optimization across all process nodes and design styles while minimizing resource usage and tapeout schedules.