Foundry news

Foundry events

TSMC NA Technology Symposium 2025

Join Siemens EDA at TSMC's North America Technology Symposium in person, in Santa Clara, California Wednesday, April 23th, 2025.

April 23th, 2025

Santa Clara, CA

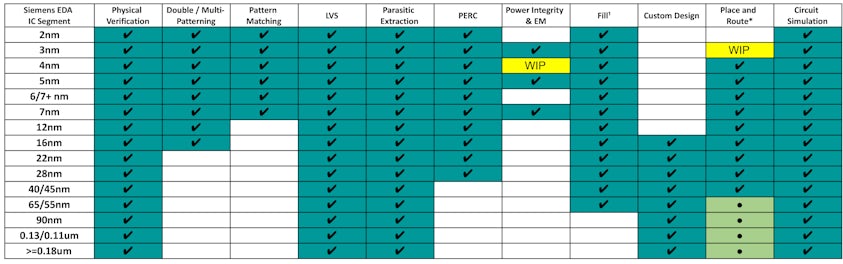

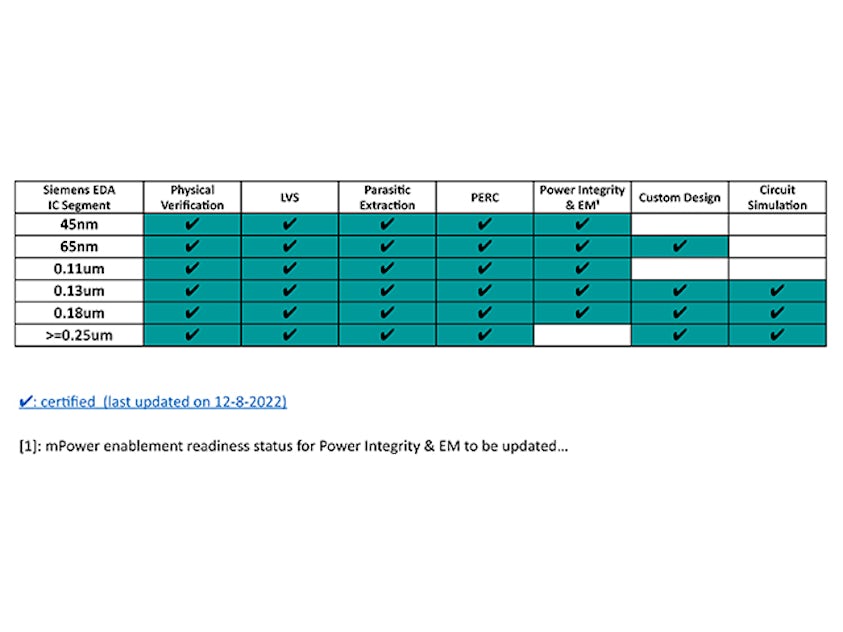

Foundry ecosystem collaboration

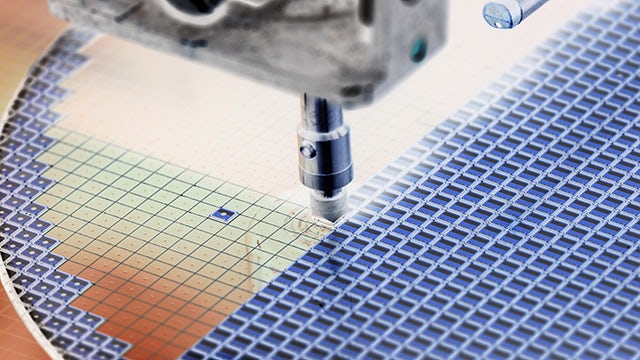

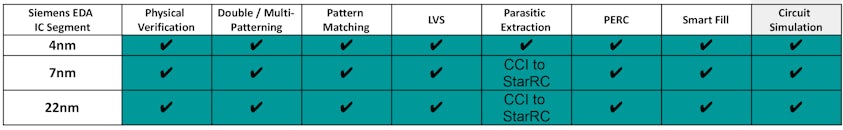

Siemens EDA tools are proven at semiconductor foundries around the globe. Collaboration with major foundries ensures the earliest access to the tools needed for advanced manufacturing processes, as well as the functionality and performance required for continued success at established process nodes.

Looking for Calibre products?

Calibre Design Solutions delivers a complete IC verification and DFM optimization platform to speed designs from creation to tapeout. Calibre Manufacturing solutions enable foundry success throughout the entire technology node lifecycle.

Ready to learn more about Calibre?

We're standing by to answer your questions! Get in touch with our team today

Call: 1-800-547-3000

Calibre consulting services

We help you adopt, deploy, customize and optimize your complex design environments. Direct access to engineering and product development lets us tap into deep domain and subject matter expertise.

Support center

The Siemens Support Center provides you with everything in one easy-to-use location -

knowledgebase, product updates, documentation, support cases, license/order information and more.

Design with Calibre blog

The Calibre tool suite delivers accurate, efficient, comprehensive IC verification and optimization across all process nodes and design styles while minimizing resource usage and tapeout schedules.